Tuning Basics

Sample Applications

ReStackor Sample Applications

Finally computer software to tune a shim stack

XR650 Suspension Tuning Using Borynack's Stacks

If you have an XR650 and don't know about Borynack's web page you should check it out. Borynack has several fork and shock shim stack configurations along with details on how to install those stacks in your bike.

A common question is how much stiffer is the Borynack's Desert stack compared to the Trail stack and how either one of those stacks compare to the stock suspension setup. That question is custom made for ReStackor. The frames below walk you through analysis of the XR650 fork compression valve using the basic Shim ReStackor code, then repeat the process with the more advanced ReStackor pro version. The comparison demonstrates the difference in the level of analysis detail in the two codes and the performance differences in Borynack's stacks.

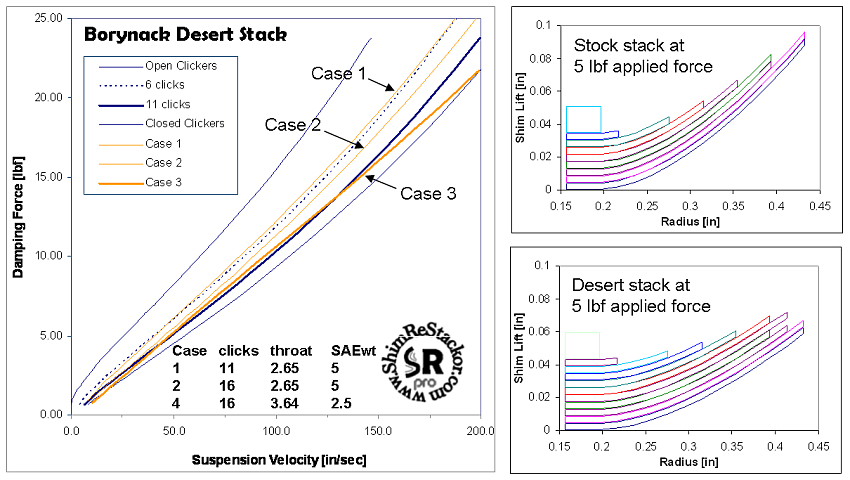

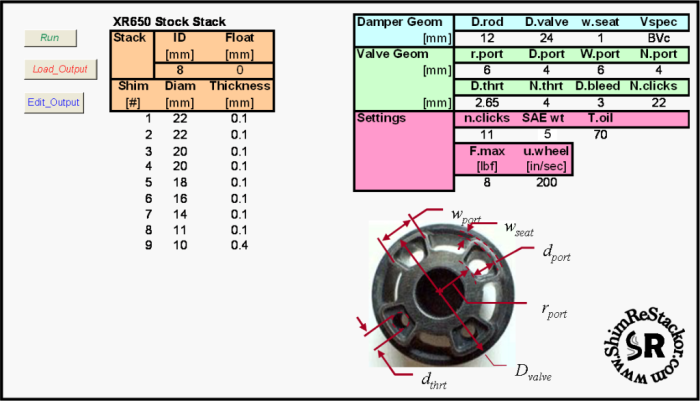

Borynack Fork Compression Valve Stacks:

![]()

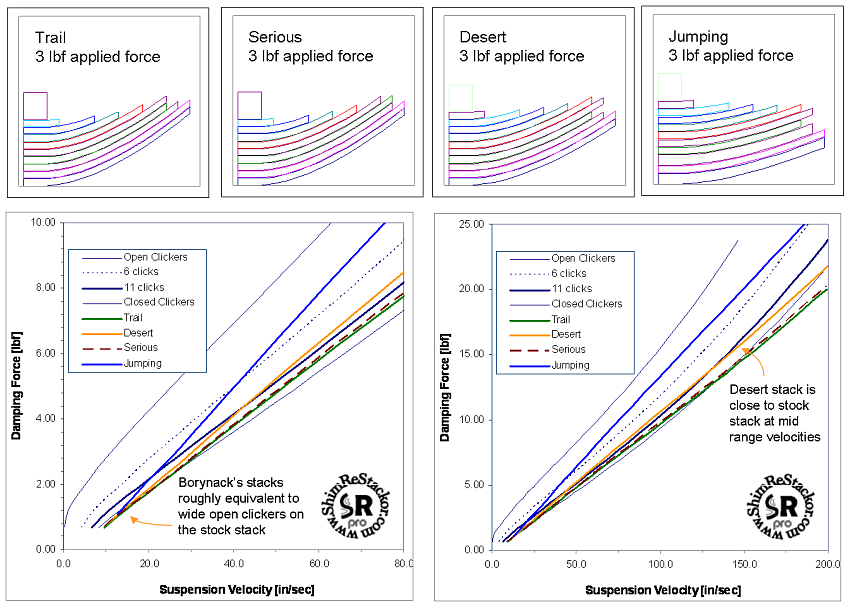

ReStackor Inputs Use Simple Valve Geometry Measurements

The entire input file for Shim ReStackor and ReStackor pro analysis of the XR650 fork compression valve is shown below:

ReStackor has been specifically designed to be simple to use. The inputs above are basic geometric measurements describing the valve geometry and the shim stack configuration. Details of setting up the ReStackor input file for an XR650 fork compression valve are here.

![]()

Shim ReStackor Calculations

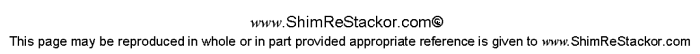

Shim ReStackor: XR650 Valve Port Diameters Limit Suspension Performance

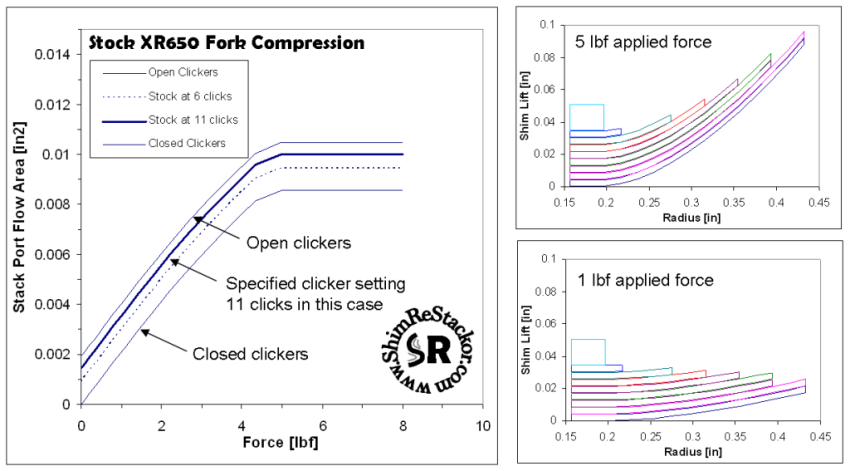

Shim ReStackor calculations compute the shim stack fluid flow area as a function force applied to the stack. The flow area computed includes the flow area through the clicker bleed circuits. Referencing the stack flow area to the clicker settings allows you to compare two valve stacks in terms of how many clicks stiffer or softer each stack will be. Shim ReStackor results for the XR650 stock valve stack "centered" at the 11 click position, out of 22 clicks, is shown below.

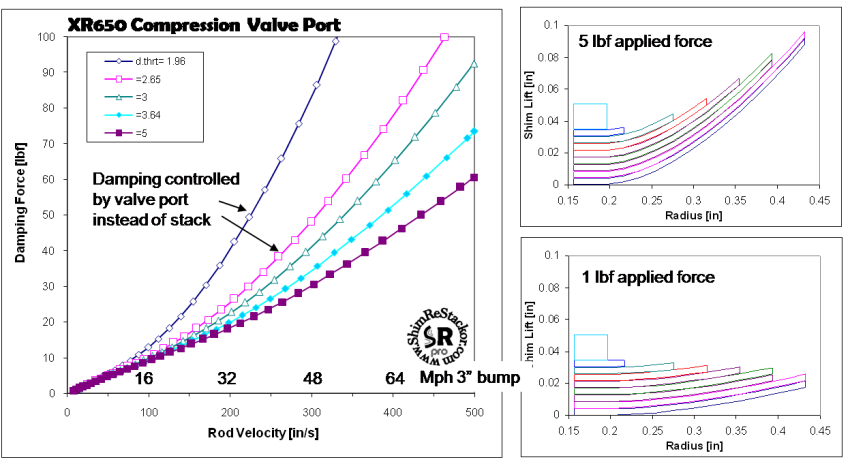

From 0 to 5 lbf the flow area through the XR650 fork compression valve smoothly increases as the shim stack is progressively deflected above the valve face. At approximately 5 lbf the flow area through the 2.65 mm valve port is smaller than the flow area through the stock shim stack. The point where the valve ports limit the flow is easily seen in the Shim ReStackor plot. The plots shows the flow area for a single valve port, the XR650 compression valve uses 4 ports.

Borynack reports that 2000 to 2004 XR650 fork compression valves use a 2.65 mm port diameter and the 2005 XR650 uses a 1.96 mm diameter port. The smaller 1.96 mm port limits the valve flow above stack forces of 2 lbf. The larger 2.65mm port limits flow above stack forces of 5 lbf. Borynack recommends drilling out the stock compression valve ports to a diameter of 3.64 mm, this allows the shim stack to control the valve flow up to stack forces of approximately 18 lbf and much higher suspension speeds.

Above stack deflections of 5 lbf the stock XR650 valve ports limit oil flow rates.

HOWTO run Shim ReStackor to produce this plot.

These results beg the question "At what bump height and suspension velocity does the stack reach a 5 lbf force level?". To answer that question the more advance fluid dynamic calculations of ReStackor pro are needed to relate the suspension velocity to the fluid dynamic forces applied to the stack face. These ReStackor pro results are discussed further down in this thread.

![]()

Shim ReStackor: Clicker Settings

With Shim ReStackor it is a simple exercise to create a clicker map plotting the shim stack flow area over the range of clicker settings from wide opened to closed. The clicker map lets you compare potential shim stack modifications to the stack you are currently riding and evaluate stack stiffness differences in terms of clicker settings. This simple exercise can save you a huge amount of time in suspension tuning by preventing you from wasting your time installing and testing stacks that are way to stiff or modifications that are so slight they make no real difference when riding the bike.

Clicker map for the stock XR650 fork compression valve. The wide open and closed clicker positions let you compare stack modifications relative to the stack you are currently riding.

HOWTO run Shim ReStackor to produce this plot

![]()

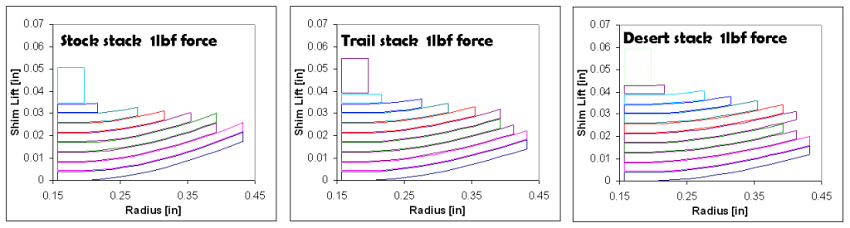

Shim ReStackor: Borynack Trail Stacks

Borynack's recommends running the trail stack at the 16 click position. This stack is about 24% stiffer than stock due to the addition of a 21x0.1 face shim. The difference in stiffness is apparent from the slope of the curve when compared to the stock stack.

Borynacks trail stack is initially softer than the stock stack but becomes stiffer at mid speed.

HOWTO run Shim ReStackor to produce this plot

Borynacks Trail Stack Compared to Stock Stack

Comparing the stiffness of Borynack's trail stack to the stock stack is a complex question because the stack is different everywhere. The trail stack is 24% stiffer than the stock stack, but running the trail stack at Borynack's recommended 16 click position it is actually softer than the stock stack at low speed. At mid speed the trail stack becomes a couple of clicks stiffer than the stock stack but softer again at high speed due to the increased 3.64 mm valve port diameters used in Borynacks configuration. So the trail stack is initially softer, becomes a couple of clicks stiffer at mid speed and softer again at high speed. All of that information is contained in the above Shim ReStackor plot.

The above figure demonstrates an important feature of Shim ReStackor. The code gives you the capability to have a pretty good idea of what a stack will be like before you even ride it. This gives you the capability to carefully select the features of the stack before spending the time to install the stack in your bike. Also, since you know where the modified stack is different from the stock stack you have a good idea of where you want to test the stack and the clicker settings you will want to use. These basic features give you the capability to tune a shim stack far beyond levels previously possible.

Trail stack:

-

Softer at low speed

-

Slightly stiffer at mid speed

-

Softer again at high speed.

Beyond the effects of stack stiffness Borynack recommends running the stack with 2.5 wt oil instead of the stock 5 wt oil. This further reduces the effective stiffness of the trail stack at low speed. The effects of oil viscosity on this stack are discussed further down in this thread in the ReStackor pro results.

![]()

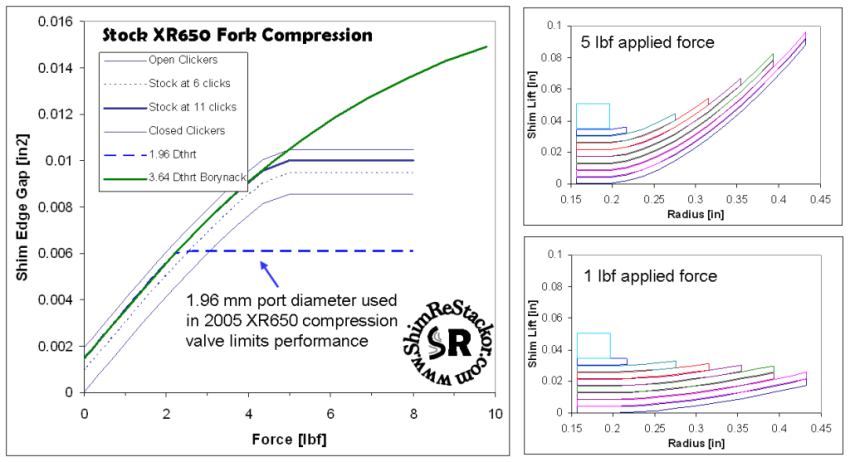

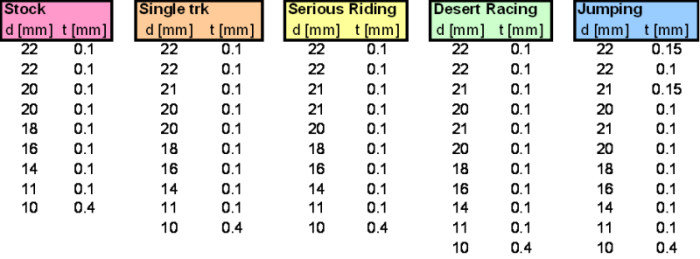

Shim ReStackor: Borynack Fork Compression Valve Stacks

Borynack has other options for the fork compression stacks on his web site. His "serious riding" stack is very close to the trail stack in terms of stiffness. The Desert stack just clips the zero click position of the stock stack at high speed and after that point the stock stack becomes significantly stiffer due to the valve port restriction. Based on these Shim ReStackor calculations the jumping stack is off the chart in terms of clicker settings compared to the stock stack, but as previously mentioned, Borynack runs these stacks with the modified valve port and 2.5 wt oil which will significantly soften the effective stiffness of these stack.

Shim ReStackor comparison of Borynacks stacks to the stock XR650 fork compression valve.

Borynack also has stack recommendations for the rebound circuit as well as the shock valving. Check it out. Borynack.com

![]()

ReStackor pro Calculations

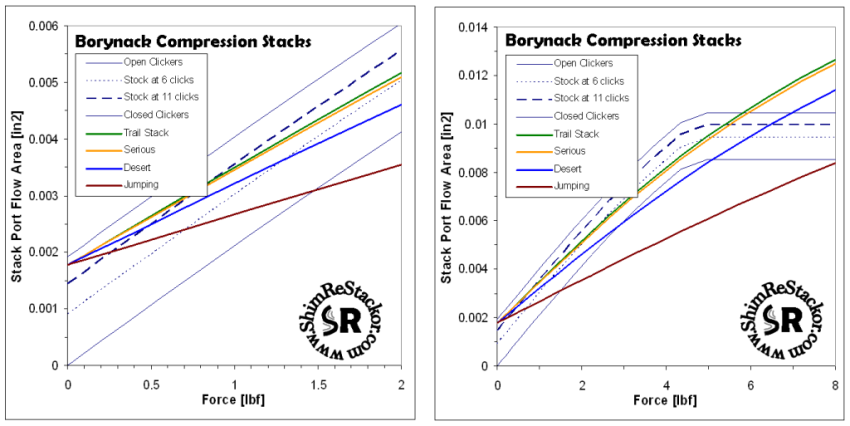

ReStackor pro Computes Wheel Speeds Where Valve Throat Restriction Limit Performance

ReStackor pro uses the stack stiffness and shim deflection calculations of Shim ReStackor and adds the capability to compute fluid dynamic flow losses and forces through the suspension circuits. This gives ReStackor pro the capabilty to connect stack stiffness, valve flow rates and shock absorber damping forces to the suspension velocity. With this added capability ReStackor pro can compute the suspension speed and bump height where the flow restrictions of the stock XR650 valve ports effect the suspension performance.

The 2005 XR650 uses a 1.96 mm valve port diameter and the 2000 to 2004 XR650 uses a 2.65 mm valve port. Borynack recommends drilling those ports to a diameter of 3.64 mm. Fork velocities where the valve port diameter begins to effect suspension performance are shown below. All cases were run with the clickers at the 11 click position.

ReStackor pro calculations show the stock valve ports limit suspension flow rates for bumps larger than two inches.

HOWTO make this plot in ReStackor pro

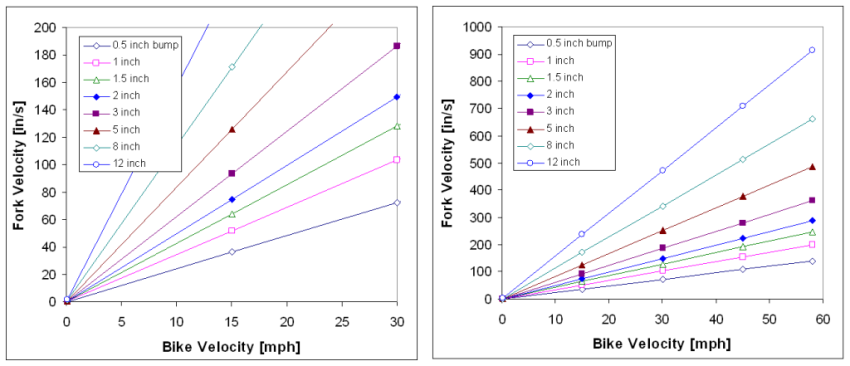

The small 1.96 mm diameter ports used in the 2005 XR650 are very restrictive and effect fork compression damping above wheel velocities of 50 in/sec. The larger 2.65 mm valve port used in the 2000 to 2004 bikes begins to effect damping rates above 75 in/sec. At a velocity of 50 in/sec 12 inches of fork travel would be used up in 0.24 seconds. That sounds fast, but before jumping to that conclusion it is important to understand that suspension are required to respond at extremely high velocities. The charts below from the ReStackor users manual relate bike velocity, bump height and the suspension velocity.

A five inch bump hieght at 30 mph produces a suspension velocity of 250 in/sec.

A suspension velocity of 50 in/sec occurs on a two inch bump hit at 15 mph. This is the limit for the 1.96 mm port diameter. The larger 2.65 mm port limits valve flow at 75 in/sec roughly equivalent to a one inch bump hit at 25 mph. The XR650 fork compression valve needs a larger port diameter, as already pointed out by Borynack. The 3.64 mm port diameter recommended by Borynack provides good suspension performance up to velocities of at least 200 in/sec and a much larger bump height.

![]()

ReStackor pro helps you evaluate the effect of valve port flow restrictions at high suspension velocities

Having the valve port throat diameter control flow rates through the valve is not necessarily a bad thing. With a restrictive port you can run a very soft, and plush, valve stack for smooth low speed suspension control and rely on the flow restriction of the valve port to keep the suspension from blowing through its stroke on large hits. Here, the valve restriction is used as a tunable element of the suspension. For the stock XR650 configuration the valve port restriction kicks in way to early. As Borynack has already pointed out, the bike needs a larger valve port throat diameter. The chart below uses ReStackor pro to evaluate your design options. A port diameter of 3.64 mm is the limit of what you can fit between the valve seats. Diameters up to 5mm were run to evaluate the performance using an aftermarket valve with larger ports.

Valve port flow restrictions can be tuned with ReStackor pro to keep the suspension from blowing-through its stroke at high speed.

The stock 2.65mm valve port diameter in the XR650 limits flow on a modest two inch bump hit at 15 mph. So we are going to pick a new design target, say a 3 inch bump at 30 mph. Inspection of the wheel velocity chart shows we need a 200 inch/sec wheel velocity for a 3 inch bump at 30 mph. With that as the target the 3.64 mm valve port recommended by Borynack would do the trick. Further increasing the valve port diameter reduces damping forces by about 10 lbf at 500 in/sec and produces a more linear damping curve.

ReStackor pro gives you the capability to evaluate the effect of valve port flow restrictions on suspension performance and tune the valve ports to provide specific suspension damping forces at a specific suspension velocities. This gives you the capability to modify the stock valve or evaluate the effects of replacing the stock valve with various aftermarket valves and determine the effect of those valves at different suspension velocities. With ReStackor pro you can not only diagnose the limits of your suspension but also tune those limits to optimize suspension performance.

![]()

Tuning Valve Ports with ReStackor pro

Some will roll their eyes at the conclusion that the XR650 valve ports are too small, most tuners already know this. But consider this. Suppose you got the first XR650 rolling off the assembly line. You take it for your first ride and discover the forks are too stiff. After experimenting with the clickers you determine the low speed damping is OK it is just some sort of mid stroke harshness and, based on your "butt" dyno results, decide to experiment with some lighter weight fork oil. You bring the bike home, drain the forks, and discover the now infamous whale snot fork oil. Thinking you have found the problem you refill the forks with 5 wt oil and head out the next weekend to discover the forks are still stiff. So you try 2.5 wt oil, I have no idea where Borynack finds this stuff, but you put it in and the forks are still harsh. You bring the bike home and pull out a compression shim, still stiff. Pull another and try again. After a couple of stack tuning attempts you come to realize there is something else wrong and, based on intuition and a guess, decide it may be the valve port diameter. You think about drilling it. But before taking a drill bit to this irreversible change to the valve port you need to decide on a size. So you try and sneak up on it, drill it some, take a test ride, discover it needs a stiffer stack. Put that in, it helps, but you still need a bigger port so you drill it again. This process could take weeks if you ride the bike every day. If you are a weekend rider the process would take months.

With ReStackor, you could discover the valve ports were limiting the suspension performance on any bump bigger than two inches without even riding the bike. Beyond that, ReStackor could retune the valve port to set the bump height where the port restriction kicks in and tune the valve port in concert with the stack stiffness to arrive at the final suspension setup. The capability to do that in software and confidently modify the valve port without guessing where the problem might be is a huge savings in time, a huge improvement in your capability to tune the valve port and valve stack in concert and a huge advancement in your capability to tune a suspension.

For those rolling there eyes at the ReStackor conclusion that the XR650 valve ports are too small. Everyone knows that and ReStackor knows it to. The difference is ReStackor is capable of accurately evaluating this same effect in any other suspension, and that is a huge difference.

![]()

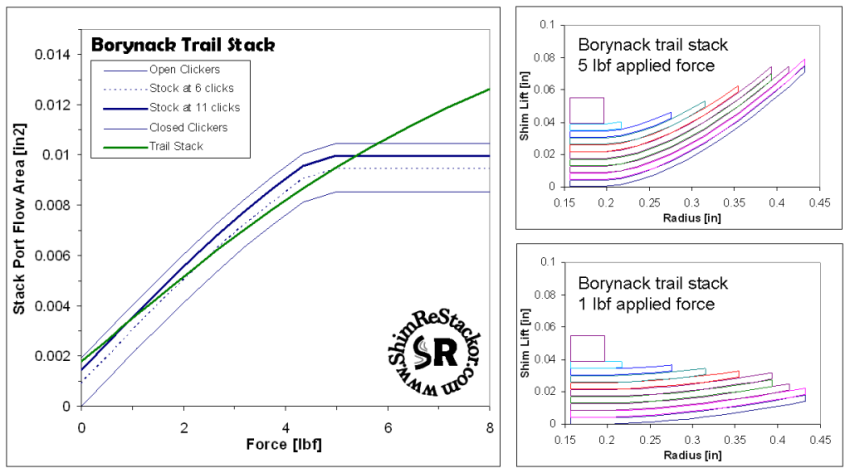

ReStackor pro: Low Speed Damping Force

At low suspension speeds the oil flow velocities through the suspension circuits are low and viscous dominated. This is further compounded by the high surface to flow area ratio through the valve shim stack when the stack is barely cracked open. These two effects combine to create a damping spike at low suspension velocities.

This effect can be seen in the ReStackor pro plots for the damping rates of the XR650 fork compression valve at low speed. The effect is more easily seen by plotting the shock absorber damping coefficient, simply defined as the damping force produced by the shock divided by the shock shaft velocity [lbf/(in/sec)].

Plotting the shock damping coefficient shows a mild damping spike for the stock valve configuration when run at the 11 click position and a higher spike when run at the 6 click position. This behavior, a damping coefficient that decreases with wheel velocity, is known as a digressive damping curve.

ReStackor pro gives you the capability to tune the shim stack and oil viscosity to produce progressive or digressive damping curves.

HOWTO create this plot in ReStackor pro

Digressive damping curves produce a stiff suspension at low wheel velocities and a potentially a harsh ride. The up side is the stiff damping rates help when you are wrestling the bike into or out of a corner. The stiff damping feeds small steering corrections directly to the wheel and keeps the bike from feeling vague or wallowing into a corner. The stiff initial rate also keeps the front suspension from tucking.

The downside is the stiff initial rate creates a harsh ride and a ride that remains harsh until a large enough bump is hit to pound the suspension through the initial damping spike into the softer damping rates at higher wheel velocities.

The trick to tuning a digressive damping curve is to find an initial rate low enough to provide initial bump plushness yet high enough to keep the bikes tip-in turning performance from feeling vague or in the worst case tucking.

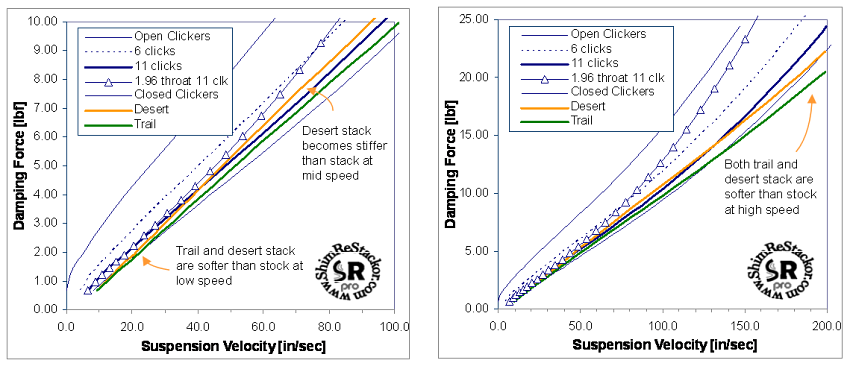

Borynack recommends running the desert stack at the 16 click position and with 2.5 wt fork oil. The damping curve for Borynack Desert stack is compared to the stock stack below.

Based on Borynacks tuning experience the initial stiffness of the X650 compression stack is too high and he recommends use of 2.5 wt oil with the clickers set at 16. This removes the damping spike and slightly reduces the low speed damping rates. The draw back of elimination of the digressive behavior of the stock suspension system may be a tendency for the suspension to tuck under some conditions. Based on the above ReStackor results the quick fix is to go back to 5 wt oil and restore the digressive damping curve of the stock suspension.

![]()

ReStackor pro Identifies Key Effects of Stack Modifications Allowing You to Focus Tuning Efforts to Optimize those Effects

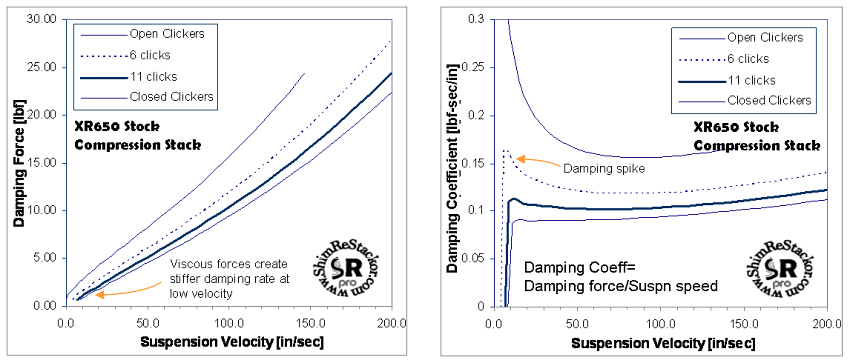

Borynack's trail stack adds a face shim to the stock stack and the desert stack adds two shims. With the addition of these shims you immediately know Borynack's stacks are going to be stiffer. With no other guidance you would expect these stacks to be stiffer across the entire range of suspension speeds.

ReStackor pro calculations show that this is not the case. The modifications recommended by Borynack effect the suspension damping rates in different ways at different suspension speeds resulting in damping rate and suspension behavior that is much different than the stock stack and much different than the "stiffer everywhere" assumption you would expect based on addition of the face shims.

Borynack recommends running the desert stack at 16 clicks. That setting makes the stack softer at low speed and when combined with the 2.5 wt oil the desert stack is actually softer than the stock stack with the clickers in the wide open position up to suspension velocities of 10 in/sec.

At mid range suspension speeds the damping rates of the desert stack quickly climb to become about 1 click stiffer than the stock stack at the 11 click position. Even though the desert shim stack is stiffer the combination of lighter weight oil and clicker settings makes the desert stack damping rates similar to the stock stack through the mid range velocities up to suspension speeds of 100 in/sec. Through this same range the damping rates of the trail stack are about 1 click softer than the stock stack.

At high speed the damping rates of the stock stack hook up due to the valve port flow restriction. Borynacks modifications drilling the valve ports to a diameter of 3.64 mm prevent this behavior and the stack damping forces remain linear up to suspension velocities of 200 in/sec.

The shim stack used in Borynack's desert stack is stiffer than the stock stack. With no other guidance the natural expectation is for the desert stack to ride stiff. The above ReStackor pro results show you the desert stack is actually softer at low speed, becomes similar to the stock stack at the 11 click position through the mid speed range and softer again at high speed. This behavior is much different from the initial expectation of the stack being stiffer everywhere.

The above ReStackor pro calculations give you insight into the expected behavior of Borynacks desert stack across the range of suspension speeds. This allows you to focus your tuning efforts. After examining the ReStackor damping curve your first ride can focus on whether the stack is softer or not at low speed. Here you can test several different clicker positions to determine the setting where the low speed performance has adequate bump compliance without allowing the suspension to feel vague or tuck on a corner entrance.

Next, since the high speed damping rates have been reduced, you can focus on the high speed performance of the stack and slam the bike into a couple of whoop faces to insure that the loss in high speed damping is not going to effect your expectation of suspension performance.

If your test rides identifies that low speed performance is better at 18 clicks out but whoop faces require the clickers to be reset to 11 clicks you now have some quantitative data you can use to draw the desired damping force curve and use ReStackor to determine the shim stack modifications needed to produce that damping profile.

This capability of ReStackor to identify the expected effects of stack modifications and retune the stack in software to match specific damping rates determined from a test ride is a huge advancement in your capability to tune a stack. This removes the guess work of just pulling a shim to see what happens. You can now design the stack to produce the performance you want and tune the shim stack to levels far beyond those previously possible.

![]()

ReStackor pro Identifies Effects of Each Modification to the Stack

The additional face shims in the desert stack make the stack stiffer than the stock. But, Borynack recommends running the desert stack at 16 clicks which will make it softer and operating the stack with 2.5 SAE wt oil. With the clickers opened up and the lighter weight oil how much stiffer will the desert stack be?

Effects of each modification is quantified below using ReStackor pro calculations starting with the desert stack installed on an unmodified stock valve.

Case 1: Installing the desert stack on the stock valve with the stock 5 wt oil and operating the stack 11 clicks out produces a damping force approximately equivalent to running the stock stack at 6 clicks.

Case 2: Installing the desert stack on the stock valve with 5 wt oil and operating the stack at 16 clicks reduces the damping to be approximately equivalent to the stock stack at 8 clicks. Due to the difference in stack structure the desert stack damping falls off slightly at high speed.

Case 3: Desert stack with the valve ports modified to a 3.64 mm diameter, operated at 16 clicks with 2.5 wt oil. At low speed the stiffer desert stack is equivalent to the stock stack at 6 clicks but the lower oil viscosity makes the desert stack behave like the stock stack with the clickers wide open. At mid speed the desert stack is very close to the stock stack run at 11 clicks. The modified ports diameters eliminate the valve restriction at high speed producing a linear damping curve up to suspension velocities of 200 in/sec. The damping forces of the stock stack begin to hook-up at velocities around 135 in/sec due to the 2.65 mm port restrictions.

Each modification produces a slightly different effect. The valve port modification produces a large effect at high speed but almost no effect at low speed. Increasing the clicker setting to 16 from the 11 click "centered" position has a medium effect and reducing the oil viscosity has a large effect at low speed. Being able to step through these cases with ReStackor gives you the capability to see the effect of each modification and customize the stack to the damping rates you desire. ReStackor gives you the capability to tune the stack far beyond levels previously possible.

![]()

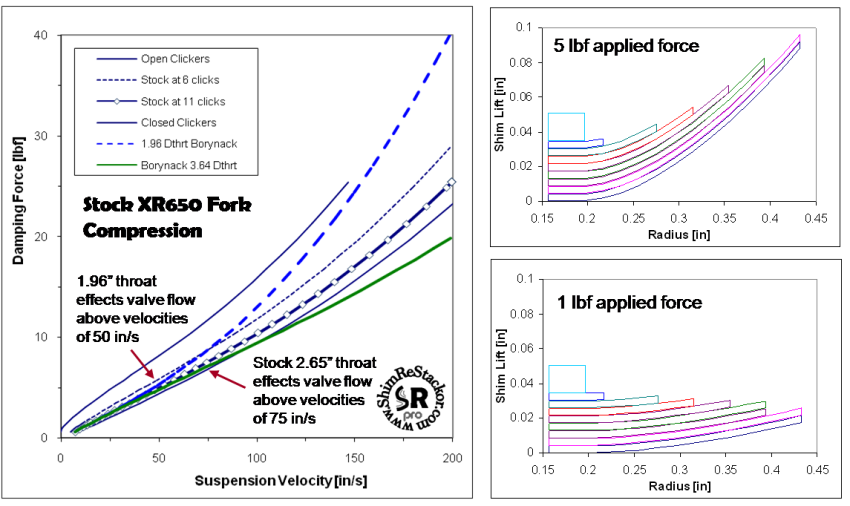

ReStackor pro: Comparison of Borynacks Fork Compression Stacks

These are the four Borynack stacks analyzed by Shim ReStackor and ReStackor pro. There are a couple of other configurations on Borynacks web site that are not included here. All stacks were run in the 16 click position with the modified 3.64 mm valve and 2.5 SAE wt oil.

The trail stack and serious riding stack are almost identical. The serious riding stack is about 1 click stiffer. Both of these stacks closely follow the stock stack with the clickers wide open. At a suspension velocity of 100 in/sec the wide open stock stack hooks up to a higher damping rate due to the valve port restriction. A suspension velocity of 100 in/sec occurs on a 3 inch bump hit at about 16 mph.

The desert stack is Borynacks favorite. At low suspension velocities the desert stack is equivalent to the stock stack with the clickers wide open. In the mid speed range (50 to 100 in/sec) the desert stack closely follows the stock stack run at 11 clicks. Above 100 in/sec the stock stack damping rates hook up due to the valve port restriction. If the trail stack is run at the 9 click position (instead of 16) it would have a similar stiffness to the desert stack.

The jumping stack is approximately equivalent to the stock stack at about 4 clicks. The biggest difference is at low speed, below 40 in/sec, where the damping rates of the jumping stack are lower due to the combination of 2.5 wt oil and the adjusters at the 16 click position. If you run the desert stack at the 3 click position you will come pretty close to matching the damping rates of the jumping stack.

![]()

ReStackor Analysis of Borynack XR650 Stacks Summary

XR650's have been around for years and there is probably more suspension tuning information for the XR than just about any other bike around. With this broad range of information the XR650 makes a great example to demonstration of the capability of the ReStackor to tune a suspension. The above examples demonstrate the capability of ReStackor to identify known XR650 suspension problems and quantify the known fixes to these real world problems.

Summary:

-

Compression valve ports are too restrictive: The baseline Shim ReStackor code was capable of identifying this problem. Fixing the problem required application of ReStackor pro to evaluate the suspension speeds and bump heights where the stock valve port restriction begin to effect performance.

-

Stiffer stack needed for large port diameter: Elimination of the valve port restriction requires the use of a stiffer stack to control high speed damping. The relationship between valve port diameter, stack stiffness and high speed damping rates were demonstrated in evaluation of Borynacks stack options.

-

Differences in Borynack's stacks quantified in terms of clicker settings: The serious riding stack is about one click stiffer than the trail stack. The desert stack is 9 clicks stiffer than the trail stack and the damping rates of the jumping stack can be duplicated by running the desert stack at about 3 clicks from full closed.

While ReStackor can be used to quantify differences in stacks you pull down off of the internet, the central purpose of ReStackor is to tune the stacks you are already riding. For the stack in your bike you can use ReStackor to retune the stack to duplicate the suspension you feel runing different oil viscosities. If you want 10 wt damping at low speed and 2.5 wt damping at high speed ReStackor can help you retune the stack to match those damping rates or tune the stack to match specific clicker settings at specific suspension velocities.

The capability of ReStackor to help you retune the valve stack without having to guess which shim to pull or where a crossover shim might go is a huge break through in stack tuning. ReStackor gives you the capability to tune your suspension far beyond levels previously possible.